Lean Consulting and Business Engineering Sample Cases

Reengineering of Production System of a Frac Tank Manufacturing Facility.

Restults: Reduced costs $5.99M or 32% by switching from batch to inline manufacturing process.

|

|

|

|

Evaluation of the Current Status of a Special Wire Products Factory, and Proposal to Improve its Operability.

Result: Implementation of a forecasted production plan and inventory levels that increased EBITDA by 13%

|

|

|

Analysis, Diagnosis and Optimization of Production of PVC Plumbing Connectors.

Results: Improved efficiency from 72.8% to 98.2% (27.4% improvement)

|

|

|

|

Strategies, Responsibilities and Values of a Quality Philosophy and its Application to the Packaging Industry

Results: 52.5% reduction in rework

|

|

|

Preliminary Study for the Improvement of the Procurement Process for Immobilized Units of Ford Motor Company in Mexico.

Result: Reduction of immobilized units by 17.39%

|

|

|

|

|

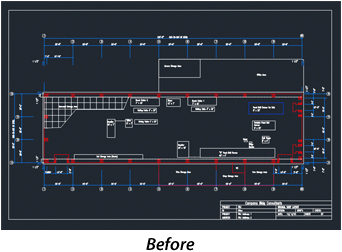

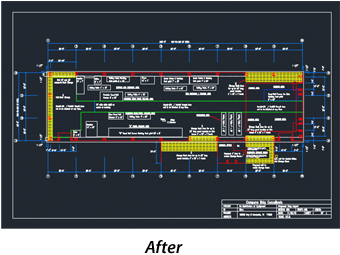

Optimization of Plant Equipment Layout to Improve Efficiency and Reduce Handling Times and Maximize Storage Areas in a Metal Panel Manufacturing Facility

Result: 53% Reduction of Material Handling and 91% Increase in Storage Areas

|

|

|

|

Study of the Batch Production System, Compared with the In Line System and Suggestions for Implementation for a Furniture and Decorative Accessories Factory.

Results: Increased production output by 13% and cost savings per product unit of 8.06 %

|

Proposal for Improving Production of a Textile Embroidery Company.

Result: Production cost reduction of 30.6%

|

|

|

|

|

|

|

Proposal and Justification of an Industrial Food (bread) Plant Through the Optimization of Manufacturing Methods and Procedures.

Result: reduction of production time by 29.4 % and production output improvement of 53.7%

|

|

Restructuring of a Sausages Processing Plant

Result: cost reduction of 7.4% and production improvement of 22%

|

|

Get started saving time and profits on your next project.

Get a Quote